Windlass Functional Sword Construction The Windlass Sword

With the advance of technology over 100 years ago, swords became quaint curiosities. Modern copies were no longer required to actually function. With no battlefield feedback from real warriors, manufacturers lost touch with how to make fully functioning swords. The emphasis switched to appearance. These swords swim against the tide and are just as functional as the originals. These swords look like the originals, feel like the originals, flex and balance like the originals, and finally, can actually cut like the originals! You get a strong sense of awe and respect for the power of these weapons that others can not generate. Reliks is proud to offer the Windlass Steelcrafts® line, who's research and development department is continuously focused on improving quality and developing new designs that are historically accurate in form and function while using proper methods and materials to achieve this goal.

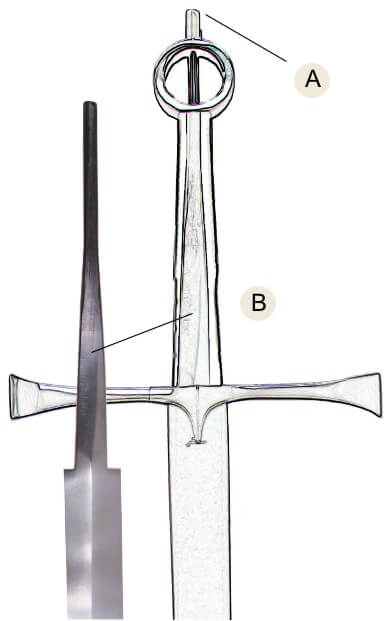

Peened & Threaded Construction

(A) The tang extends straight through the cross guard, handle and the pommel. At this point the end of the tang is peened. Peening a sword is much like making a rivet. You would mushroom over the end of the tang to pull the entire sword together. Another method that is historically accurate is a threaded construction. This is where the end of the tang is threaded and the pommel is screwed over the tang.

Tang

(B)The tang is forged as a part of the blade. This historical accuracy gives it the strength and durability required for a functional sword. Windlass Steelcrafts® is dedicated into carrying out this tradition with all of their battle ready swords to ensure that they rival the originals.

Many sword blades today are made in two separate pieces where the tang would be welded onto the blade. The tang is sometimes nothing more then a threaded rod welded to the blade referred to as a "rat tail". This is done to reduce cost and is only good for a decorative sword.

Tempering, Flex and Taper

One of the biggest misconceptions about swords is that they should be large rigid masses of steel. This in fact couldn't be further from the truth. A true medieval blade was light, strong and flexible. Unlike many of the strictly decorative stainless steel swords on the market today the Windlass Steelcrafts® sword is true to size, weight, appearance and flex. Each blade is true to the requirements of the original swords from each time period and are capable of flexing up to 5 inches while returning to its true shape.

Without this flexibility a sword would never hold up in battle. The flex works to absorb the shock of a striking blow against another sword or armour. Without this ability the blade is exposed to a high amount of torque upon impact which could cause it to warp, bend or possibly break.

Windlass Steelcrafts® blades also have a distal taper. This means the blade is thicker at the crossguard and gradually become thinner towards the tip. This effects the balance producing a more flexible and lighter blade.

Meeting these strict requirements is achieved by generations of experienced Windlass Steelcrafts® blade smiths and proper controlled tempering processes during forging.

The Result of Honoring the Past

Windlass Steelcrafts® are producing authentic historically accurate reproductions with the same methods used by their ancient predecessors. Each blade being hand forged in a semi-production environment by accomplished blade smiths. The result of this labor of love is unmatched even by today's most modern equipment.

This example of a XVIIIa sword (left) produced by Windlass Steelcrafts® says more than a thousand words and shows the simple beauty and perfection that can be achieved by skilled craftsmen. By producing swords in this fashion no authenticity is lost by using modern machine perfect techniques. Each piece retains its own individual distinct character while being a formidable weapon that could hold its own on the medieval battlefield.

Original Photograph (right) is published in "Records of the Medieval Sword" By Ewart Oakeshott