The Decorative Sword vs. The Functional Sword

In this article we are going to have a look at the functional sword and the decorative sword and explain the key differences between them. This article is not a competition between decorative and functional swords, as they both are produced differently for their intended purpose. The intent is to explain how we determine which swords are safe to use and which swords are best left on the wall.

Is it all in the Steel?

There are many types of steel that will be found in the swords we offer but there are major differences found between the decorative swords and the functional swords. The steel selection is made based on the purpose or use of the sword. The decorative sword will normally be made with a stainless steel blade because its purpose is to be a display piece and stainless steel offers corrosion resistance and low maintenance. This makes stainless steel ideal for decoration but a poor selection for a functional sword. Stainless steels are too hard and brittle in long spans which can break, fracture or bend under the high impacts that swords endure during re-enacting or cutting.Functional swords can be constructed from a variety of steels. Many people think of the legendary Damascus steel used by vikings or the famous folded steel used in the Japanese samurai sword. These are not types of steel but forging techniques that were used to make impure steels stronger when swords were forged from poor carbon sand irons hundreds of years ago. The functional sword today is forged from a very pure high carbon steel which no longer lacks strength because of the impurities. Folded and Damascus swords are beautiful swords and are still produced by functional sword makers today paying homage to the past, but don't confuse them as being stronger than a properly produced high carbon steel blade. Some decorative swords will also use carbon steels but they are pressed or cut into the shape of a sword blade and not forged like a proper functional sword. Proper sword forging will re-align the carbon in the blade and with good tempering, make the sword stronger and more durable.

What about the Tang?

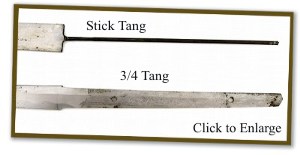

The tang is the hidden piece of metal that is under the handle that in most swords you can't see until you have taken the sword apart. The tang can vary in shape, length and construction method. The good news for the decorative sword is all tang types will work. The only purpose for the tang on a decorative sword is to hold the hilt to the blade. This is where manufacturers came up with what is known as the “rat tail” tang or its equivalent, “the stick” tang. These two tangs are a long thin metal rod that is welded to the shoulder of the blade just under the guard, running the length of the handle and secures everything to the blade with either a nut or sometimes the pommel will be threaded onto the rod. This method of construction is exclusive to the decorative sword. This tang is sufficient and strong enough to construct a solid display sword but is not strong enough for repeated impact or the high speed start and stop motions of sword demonstrations and use. The rat-tail or stick tang design fails under repeated use and could be very dangerous to the wielder or anyone else within the blades flight path when the rod lets go of the blade.The tangs found in functional swords are much stronger. There are several functional tang types but the two most common are the traditional “3/4 Tang” found in most functional Japanese swords and the “full tang” found in most functional European swords. The “3/4 Tang” is just as strong as the full tang sword and on many websites you will see the 3/4 tang being mistakenly referred to as a full tang because of the popularity of the term. The 3/4 tang runs past the hand grip positions of the katana handle and stops short of being exposed at the end of the handle. The tang is nearly the same width of the blade and gradually tapers until the end. This is a substantial amount of steel to stand up to the high amount of torque the blade needs to withstand during sword use. The full tang is just as strong as the 3/4 tang. The only difference being is the tang is extended through the end of the handle where it is threaded or peened to secure the hilt to the blade.

Temper, Quenching and Flex

This section does not apply to the decorative sword as it is not needed for aesthetics or display. Properly tempering a functional blade is crucial for a swords performance. There is a misconception that swords are long heavy solid pieces of steel that do not bend or flex. This is true if you are describing a decorative sword that is not intended for use. As for the functional sword, this belief is false on every account. Most historically accurate functional swords weigh no more than 2-3 lbs. A large great sword may come in around the 4 lb mark. Production of a functional sword blade requires an experienced blade smith with a great knowledge of metallurgy. There is a delicate balance of heating and quenching that greatly affects the steels hardness, flexibility or rigidity. The smith will temper a functional blade so it will flex and return to its true shape. If the blade is too hard it will remain bent, fracture or break when put under stress.The Japanese sword smiths take tempering to a different level with a process called “differential tempering”. During the heating and quenching process the forged Japanese blades spine will be covered with clay. This is done to cool the spine a slower speed than the cutting edge producing a blade with a hard edge that will retain its sharpness and a softer spine to flex the blade on impact. The differential tempering process also gives the Japanese sword its curve and hamon. The traditional Japanese blade is forged straight and the curve is naturally produced during the tempering process. This is by far the hardest part of sword production and many blades are lost during this process. The hamon is the “different colored” edge that you may see. This is often created by an acid etch or polishing trick on a decorative sword to give the illusion of sharpness. These same methods are often done to a functional blade as well to enhance the appearance of the hamon with the difference being that the blade was properly tempered before this technique was applied.This sums up the main and key differences between a decorative sword and a functional sword. There are many other things to consider about the quality of the functional or decorative sword such as construction, handle or hilt materials, types of adhesives (if used), pegs, thread type and more. Just remember when shopping for a functional sword and sifting through all the most used terms that "Sharpened" does not mean it's functional; "High carbon steel" doesn't mean it's functional"; "Full tang" doesn't mean it's functional. There is a combination of things that need to be considered for a safe functional sword and all others should only look great on your wall or fireplace. We have separated the two classes of sword into "functional swords" and "decorative swords" on our website to help you find the sword you are looking for.

You may like Functional Swords...